PP Non Woven Needle-Punched Sludge Filter /Dewatering Bag Dewatering Bags are an easy and economical option for any site looking to remove sediment or silt from their discharge. Constructed from a robust geotextile filter fabric, these bags catch and contain sediment as it is being pumped from your site.

PP Non Woven Needle-Punched Sludge Filter /Dewatering Bag

Quick Details

Place of Origin:Jiangsu, China

Brand Name:Leebo

Model Number:DBJX--Geotextiles

Geotextile Type:Non-Woven Geotextiles

Supply Type:Make-to-Order

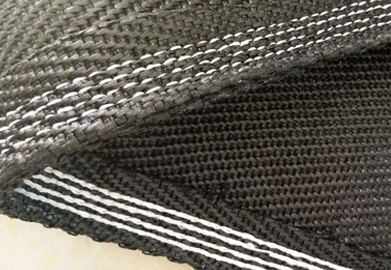

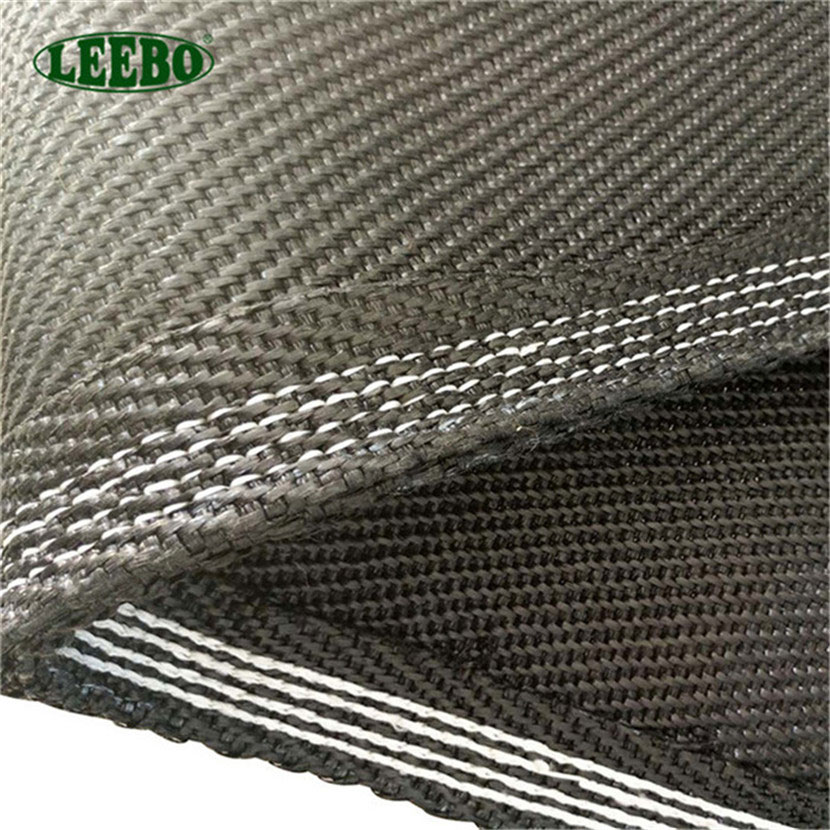

Material:100% Polypropylene

Nonwoven Technics:Needle-Punched

Pattern:Lustring

Style:Plain

Feature:Breathable, Eco-Friendly, Shrink-Resistant, Tear-Resistant, Dewatering

Usage:Agriculture, Bag, Industry, Dredging areas

Certification:ISO9001

Size:3' x 4' / 6' x 6' / 10' x 15' / 15' x 15'/Customized Size

Raw Material:100% Polypropylene (PP) Fiber

Supply Ability 60000 Carton/Cartons per Month Sludge Dewatering Geo Tube Geo Bag Geotextile Bag Dewatering sil

Packaging Details The bag in carton, cartons on pallet, moon rock packing for China wholesale Sludge Dewatering Geo Tube Geo Bag Geotextile Bag for oil & sediment

Port ShangHai/NanJing

Lead Time: Shipped in 15 days after payment

PP Non Woven Needle-Punched Sludge Filter /Dewatering Bag

Product Description

Specification

|

Color |

Black |

|

Material |

100% Polypropylene |

|

Size |

3' x 4' / 6' x 6' / 10' x 15' / 15' x 15'/Customized Size |

|

Weight |

265gsm |

|

Width |

91.5cm / 183cm / 305cm / 457cm |

|

Process |

Lustring PP fabric, Sewing, Packing |

|

Application |

Contain sediment and oil pumped out during dewatering operations |

|

Place of origin |

Jiangsu, Mainland China |

Feature

Dewatering Bags are an easy and economical option for any site looking to remove sediment or silt from their discharge. Constructed from a robust geotextile filter fabric, these bags catch and contain sediment as it is being pumped from your site. Their combination of strength and effectiveness has made them a favorite for construction sites, power plants, dredging areas, and more. Available in Standard, Heavy Duty and Contractor options.

Use for dewatering operations with large quantities of silt, sediment, or dirt. Bags can be emptied and reused repeatedly.

Instruction

**Traditionally settlement methods (such as straw bale structures or settlement ponds/tanks) are often ineffective, rely on slow water movement, long settlement times, expensive and time consuming tank maintenance and large works areas.

**Dewatering Bags are an efficient, practical, quick, simple and cost effective alternative solution to manage this ongoing environmental problem of removing suspended solid pollutants from pumped water on construction sites.

**Sediment-laden water is simply pumped into the high quality filter bags, which trap the solids inside and allow filtered water to flow freely out through the geotextile fabric to disperse into the surrounding ground or another collection point.

**Dewatering Bags can also be used for gravity feed applications such as outfall pipes from site drainage or lagoons.

**The silt filter bags provide a passive non-mechanical solution, without the use of excessive or specialist machinery (other than possible lifting equipment when full), and do not require a large work area.

**The sediment bags are also light, compact and easy to store, with minimal cleaning up required - when full just dispose of the bag and replace with another bag.

**The Dewatering Bags detain both oil and sediment, offering a combination of benefits not available in alternative products. They can also be used to contain contaminated sediment whilst treatments are applied (such as flocculants or absorbents).

**The standard 1.80 x 1.80m Dewatering bags has the capacity to trap near 1 tonne of silt and cope with flow rates up to 2,730 l/min, while the larger 3.05 x 4.55m bags can trap over 4 tonnes of silt and cope with flow rates up to 6,818 l/min.

PP Non Woven Needle-Punched Sludge Filter

PP Non Woven Needle-Punched Sludge Filter High density factory non woven geotextiles for geotube dewatering

High density factory non woven geotextiles for geotube dewatering Geotextile geotube to protect coasts survives sea erosion season geotube

Geotextile geotube to protect coasts survives sea erosion season geotube 100%PP Woven China Supplier Sludge Dewatering Geotextile Tubes

100%PP Woven China Supplier Sludge Dewatering Geotextile Tubes Polyester/pp woven geotextiles fabric for geo bags and geotubes

Polyester/pp woven geotextiles fabric for geo bags and geotubes